Multicomponent Distillation Column with a Sidestream

Requires a Wolfram Notebook System

Interact on desktop, mobile and cloud with the free Wolfram Player or other Wolfram Language products.

Consider a distillation column operating at 101.325 kPa and separating an equimolar mixture of benzene ( ), toluene (

), toluene ( ), and

), and  ‐xylene (

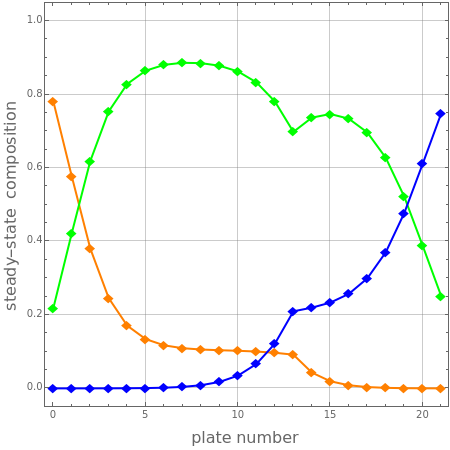

‐xylene ( ). The column has 20 stages, a partial reboiler, and a total condenser. The feed location is stage 13 counting from the top. The feed, a saturated liquid, has a flow rate equal to 100 kmole/hr. The column has a liquid sidestream at stage 7 counting from the top. You can set the draw rate of this sidestream as well as the reflux and reboil ratios of the column. The Demonstration plots the composition profile in orange, green, and blue for benzene, toluene, and

). The column has 20 stages, a partial reboiler, and a total condenser. The feed location is stage 13 counting from the top. The feed, a saturated liquid, has a flow rate equal to 100 kmole/hr. The column has a liquid sidestream at stage 7 counting from the top. You can set the draw rate of this sidestream as well as the reflux and reboil ratios of the column. The Demonstration plots the composition profile in orange, green, and blue for benzene, toluene, and  ‐xylene, respectively. Plots of the temperature profile and liquid and vapor flow rates can also be displayed by choosing the appropriate tabs. Both composition and flow rate of the column's feed and product streams can be seen using the column output tab. The variables

‐xylene, respectively. Plots of the temperature profile and liquid and vapor flow rates can also be displayed by choosing the appropriate tabs. Both composition and flow rate of the column's feed and product streams can be seen using the column output tab. The variables  ,

,  ,

,  , and

, and  stand for feed, distillate, residue, and sidestream flow rates, respectively. You can easily check that the overall and components mass balance are verified.

stand for feed, distillate, residue, and sidestream flow rates, respectively. You can easily check that the overall and components mass balance are verified.

Contributed by: Housam Binous, Naim Faqir, and Brian G. Higgins (November 2012)

Open content licensed under CC BY-NC-SA

Snapshots

Details

The expressions for pure component vapor and liquid enthalpies were adapted from Aspen–HYSYS.

The mixture is assumed to be ideal and to obey Raoult's law.

Reference

[1] E. J. Henley and J. D. Seader, Equilibrium-Stage Separation Operations in Chemical Engineering, New York: Wiley, 1981.

Permanent Citation

"Multicomponent Distillation Column with a Sidestream"

http://demonstrations.wolfram.com/MulticomponentDistillationColumnWithASidestream/

Wolfram Demonstrations Project

Published: November 12 2012